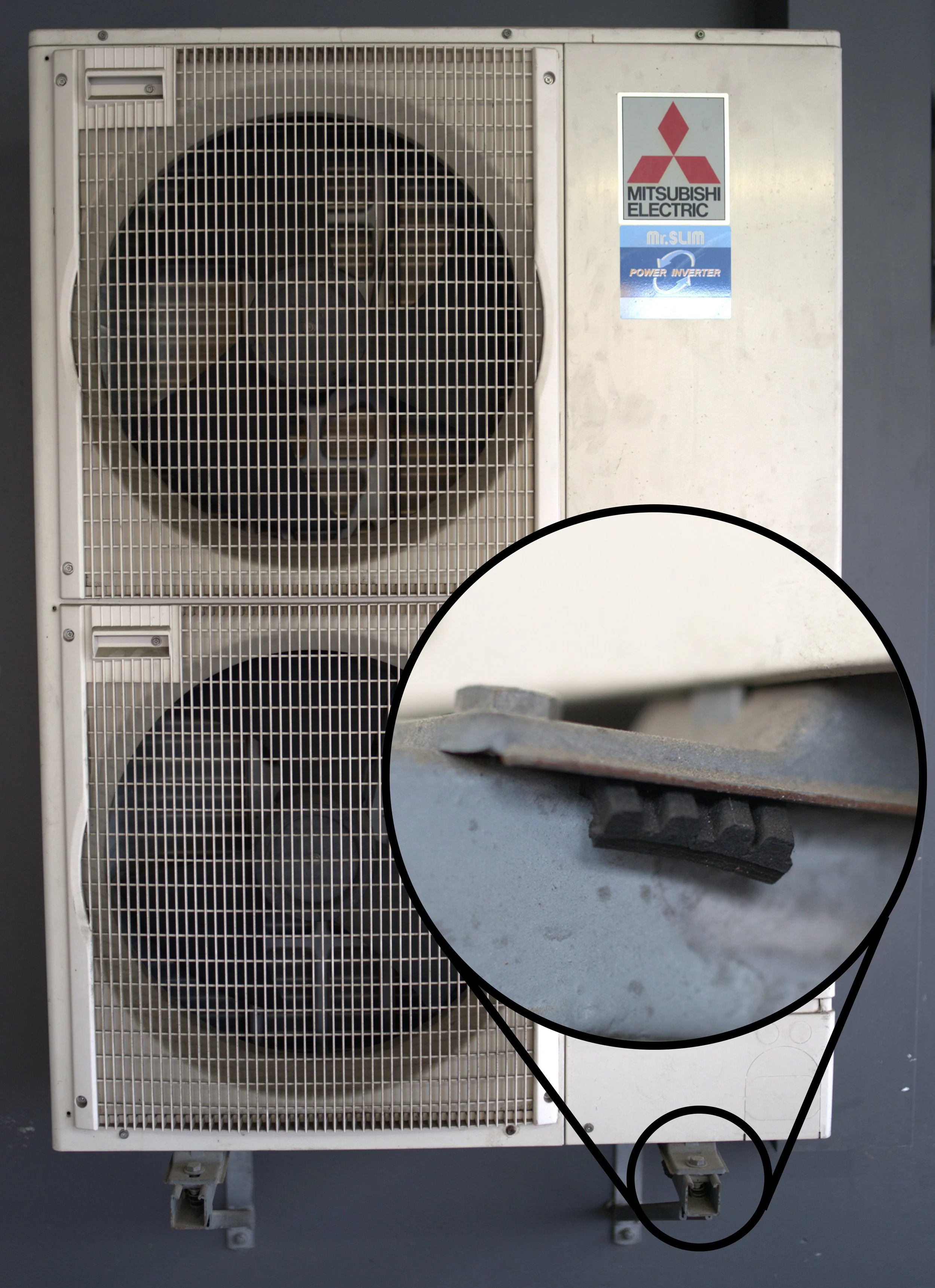

Rubber waffle pads under A/C compressors - total waste and environmental nightmare

Why are we still doing this? This has been going on for as long as I can remember, and with absolutely NO value in terms of stopping vibration. Almost every piece of waffle pad is crushed beyond belief, and so will never work as hoped. Even if it wasn’t crushed, getting the correct deflection to make some reasonable isolation would be extremely difficult.

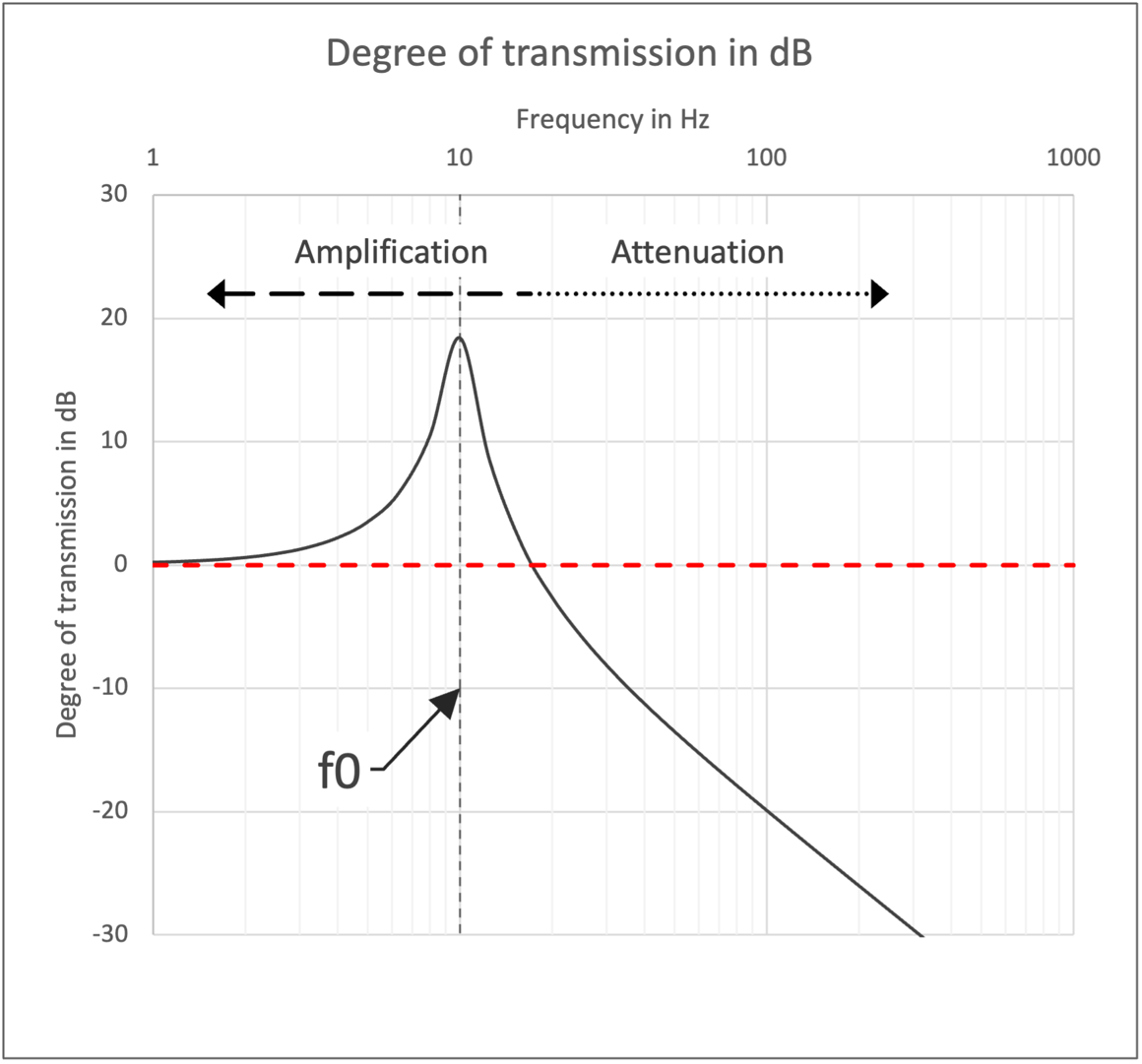

Almost all isolators need to be correctly loaded and deflected to work as designed. If they are compressed too much or not enough, they will not work as isolators, and in some cases will make the transmission of vibration worse (when the resonant frequency of the improperly loaded isolator matches the vibration of the load.

Isolator resonance is dependent on loading

The example above shows resonance at 10Hz. Attenuation starts at about 20Hz and increases as frequency goes up. At 50Hz where motors run, significant attenuation is delivered.

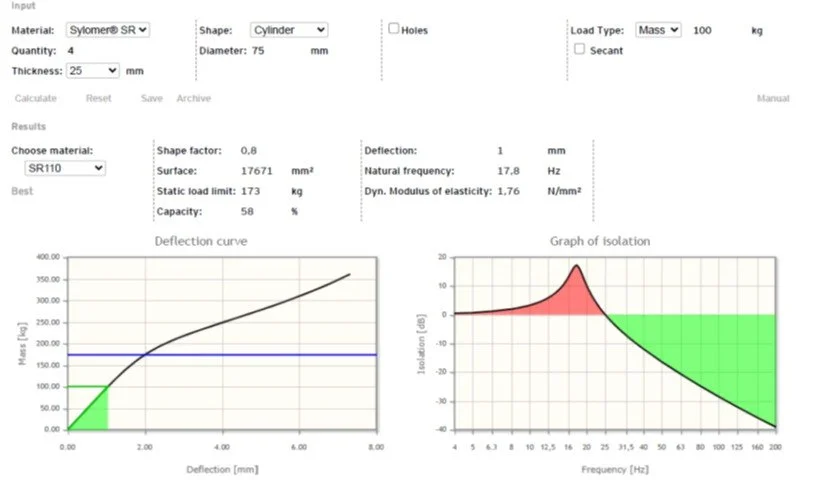

A correctly loaded isolator must be deflected the correct amount, often about 10% of original height. It is important that the shape does not unduly change and that the isolator material does not harden over time - which rubber does. Sylomer from Getzner is a good example of a suitable vibration isolator as it can be loaded/deflected properly, it maintains it’s shape and doesn’t harden significantly over time.

Air conditioning compressor with functional isolation

Typical calculation for air conditioner vibration isolation